Abstract:In the field of drilling operations, the combination of button bits and drill pipes brings forth numerous advantages tha...

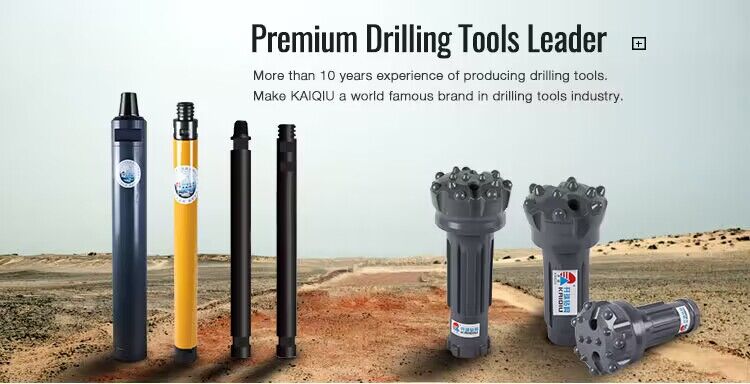

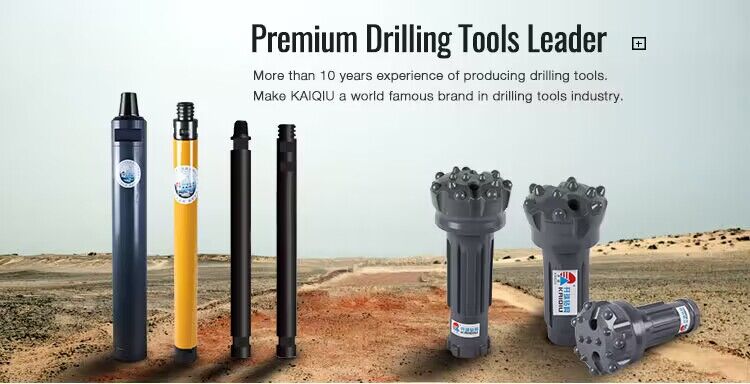

In the field of drilling operations, the combination of button bits and drill pipes brings forth numerous advantages that enhance efficiency, productivity, and safety. Button bits, also known as roller cone bits, are essential tools used in the drilling process, while drill pipes serve as the conduit for transmitting power and fluids to the drilling bit. This article explores the synergistic benefits of using button bits and drill pipes together, highlighting their role in optimizing drilling performance and achieving successful outcomes.

Enhanced Drilling Performance:

Button bits and drill pipes work in tandem to optimize drilling performance. Button bits are designed with strategically placed cones that have hardened steel teeth or tungsten carbide inserts, enabling them to efficiently crush rocks and penetrate various formations. The rotation of the drill pipe transmits torque to the button bit, facilitating the drilling process. The combination of these two components results in improved drilling speed and increased drilling depths, ultimately enhancing overall performance.

Increased Durability and Longer Service Life:

When used together, button bits and drill pipes can enhance their individual durability and extend their service life. Button bits are subjected to intense wear and tear due to the harsh drilling environment, making durability a critical factor. The rotation of the drill pipe reduces the impact load on the button bits, leading to reduced stress and wear on the cutting structure. This cooperation helps extend the lifespan of both components, resulting in cost savings and reduced downtime for maintenance or replacement.

Efficient Cuttings Removal:

Effective cuttings removal is vital for maintaining drilling efficiency and preventing blockages. The combination of button bits and drill pipes facilitates efficient cuttings removal during the drilling process. As the button bits crush the rocks, the drill pipes convey the cuttings to the surface through the hollow center of the pipe. The proper alignment and design of the drill pipe enable smooth and continuous removal of cuttings, preventing clogging and improving drilling efficiency.

Enhanced Drilling Accuracy:

Drilling accuracy is crucial for achieving precise target locations, especially in complex drilling operations. Button bits and drill pipes complement each other to enhance drilling accuracy. The design and construction of button bits provide stability and control during drilling, allowing operators to maintain a straight drilling path. The drill pipes transmit accurate torque and weight on bit (WOB) to the button bits, enabling precise steering and control. This collaboration ensures that drilling operations remain on track, minimizing deviations and improving overall accuracy.

Improved Safety Measures:

The combination of button bits and drill pipes also contributes to improved safety measures during drilling operations. The durability and extended service life of the button bits reduce the frequency of bit changes, minimizing the exposure of personnel to hazardous drilling environments. Furthermore, the efficient cuttings removal facilitated by the drill pipes helps prevent blockages, reducing the risk of equipment damage and potential accidents. By working together, button bits and drill pipes enhance safety standards and promote a secure drilling environment.

The utilization of button bits and drill pipes in tandem presents significant advantages in drilling operations. The collaboration between these two components enhances drilling performance, increases durability, facilitates efficient cuttings removal, improves drilling accuracy, and enhances safety measures. The synergistic benefits derived from using button bits and drill pipes together result in enhanced productivity, cost savings, and successful outcomes in drilling projects. As technology continues to advance, the integration of these two vital components will play a crucial role in driving the efficiency and effectiveness of drilling operations in the future.

简体中文

简体中文 English

English España

España русский

русский