Abstract:The thread drill bit is a specialized tool designed to create threaded holes with exceptional precision and efficiency. ...

The thread drill bit is a specialized tool designed to create threaded holes with exceptional precision and efficiency. It plays a crucial role in various industries, including manufacturing, construction, automotive, and aerospace. This article aims to explore the features, benefits, and applications of thread drill bits, highlighting their significant contributions to the threaded hole creation process.

Understanding Thread Drill Bits:

Thread drill bits, also known as tap drills, are cutting tools specifically designed to create pilot holes for tapping screws or creating threaded holes. They are typically made from high-speed steel (HSS) or solid carbide, known for their durability, heat resistance, and ability to withstand high rotational speeds. The thread drill bit features a pointed tip, fluted body, and a shank for secure attachment to a drilling machine.

Features and Design:

Thread drill bits come in a variety of sizes and designs, depending on the specific application and thread requirements. The primary features include:

a. Pointed Tip: The pointed tip facilitates precise hole positioning and prevents the bit from wandering during the drilling process.

b. Flutes: The fluted body of the drill bit helps in chip removal, reducing heat buildup and minimizing the risk of tool breakage.

c. Helical Shape: Thread drill bits typically have a helical shape, allowing for smooth cutting and efficient chip evacuation, resulting in cleaner, more accurate threads.

d. Shank: The shank is designed to fit securely into the drilling machine's chuck, ensuring stability during the drilling process.

Benefits of Thread Drill Bits:

The utilization of thread drill bits offers several advantages in the creation of threaded holes:

a. Increased Precision: Thread drill bits enable precise alignment and positioning, resulting in accurately threaded holes with tight tolerances.

b. Enhanced Efficiency: These specialized bits eliminate the need for multiple tools by combining the functions of drilling a pilot hole and tapping a thread, thus streamlining the hole creation process.

c. Improved Thread Quality: The helical design of thread drill bits ensures smooth and consistent thread formation, reducing the chances of thread stripping or galling.

d. Time and Cost Savings: By minimizing the need for additional tools and reducing the possibility of errors, thread drill bits contribute to improved productivity and cost-efficiency.

Applications of Thread Drill Bits:

Thread drill bits find wide applications across various industries, including:

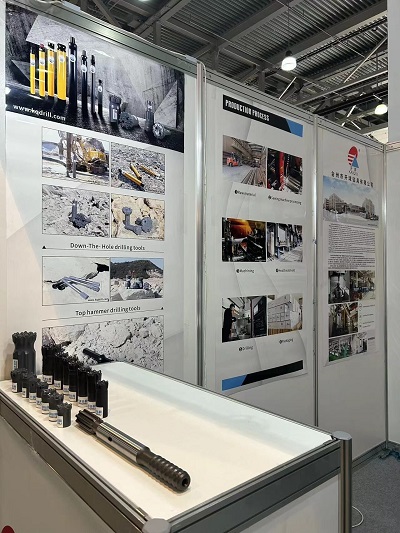

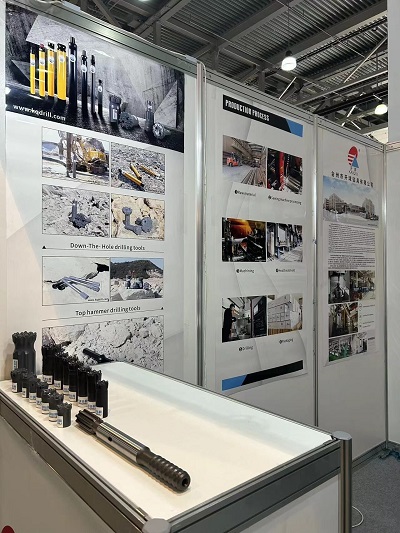

a. Manufacturing: Thread drill bits are extensively used in metalworking industries for creating threaded holes in components such as machine parts, fasteners, and assemblies.

b. Construction: These bits are crucial in construction projects involving the installation of plumbing systems, electrical connections, and HVAC equipment.

c. Automotive: Thread drill bits play a vital role in the automotive industry for assembling engines, transmissions, and other critical components.

d. Aerospace: The aerospace sector relies on thread drill bits for manufacturing aircraft components, ensuring structural integrity and reliability.

The thread drill bit and drill pipeis an indispensable tool that significantly enhances precision and efficiency in the creation of threaded holes. Its unique design, coupled with its ability to streamline the hole creation process, improves productivity and reduces costs across various industries. As technology advances, the development of more specialized and advanced thread drill bits continues to drive progress in the field of threaded hole creation, meeting the ever-growing demands for precision and quality.

简体中文

简体中文 English

English España

España русский

русский